Quaternary Ammonium Compounds- or QACs are some of the most commonly used disinfectants within the human and veterinary health and food processing industries (1,3). After discovery in the early 20th century, QACs have been used as antimicrobial and preservative agents as well as in disinfection products.

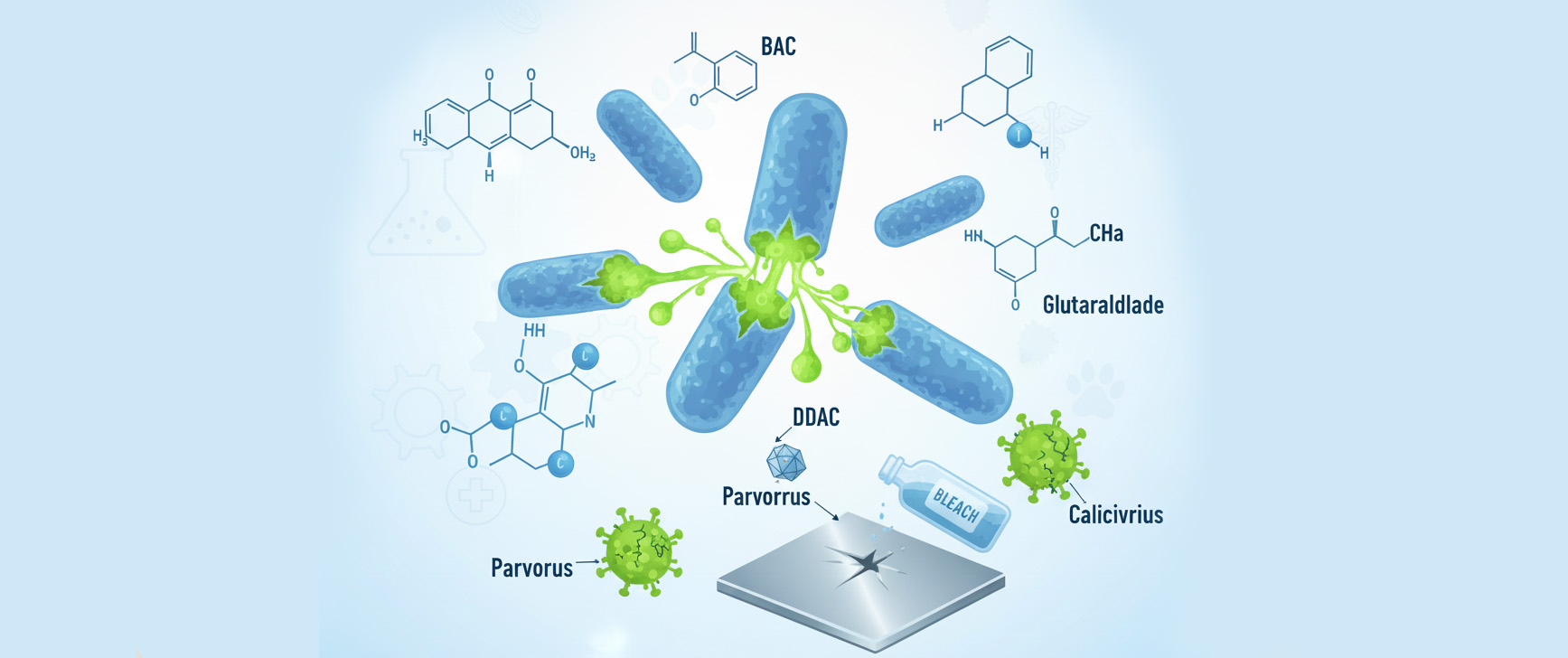

QACs work by adhering to and then disrupting the cellular membrane of microorganisms subsequently interacting with the internal cytoplasmic membrane of the bacteria (1). QACs have hydrophobic properties and so are also effective against pathogens within an environment with a high lipid content.

QACs remain very safe to use around a range of species with extremely low toxicity; they are a very cost effective option and have good compatability with surface materials and fabrics, allowing them to be used without damage compared to sodium hypochlorite (bleach) (1).

The new formulation of Safe4 includes the concentrated disinfectant (in all scents) and the pre-diluted spray- these upgraded products will be available from November 2025.

BAC, Benzalkonium chloride or benzyl ammonium chloride, remains the primary QAC in the formulation. An additional QAC (didecyl dimethyl ammonium chloride or DDAC) and additional glutaraldehyde have replaced the polyhexamethylene biguanide used in the previous formula. These two changes mean that Safe4 is not only a parvovirus virucide but is now effective against calicivirus too.

Feline calicivirus (of Caliciviridae family) is a highly contagious virus causing mild to severe respiratory disease in young cats. It does not pose a zoonotic threat; it remains species specific.

The relevance of this efficacy against feline calicivirus does however extend to human healthcare. Norovirus remains one of the most common causes of food-borne illness. As an organism, it is challenging to grow and manage in the laboratory setting to allow effective testing (3). Norovirus is also a member of the caliciviridae family and feline calicivirus is the most commonly used surrogate virus (3).

When selecting an appropriate disinfectant, it is vital that independent laboratory efficacy analysis is disclosed and not testeding by the manufacturer themselves. It is also noted that the disinfectant should be tested against individual pathogens as the measurement for success. Efficacy must be stated ‘against’ a certain pathogen and the disinfectant selected for a workplace due to this (3).

It is important to remember that while the efficacy of the active ingredient is important, the product will only work if applied correctly and consistently. QAC concentations may be compromised by 50-83% through the use of cotton mops and microfibre towels by up to 50-83% (1).

Organic load will also alter the efficacy, and dilution rates need to be adjusted to alter the concentration of QAC in this environment if thorough cleaning and removal is not performed prior to disinfection (1).

Resistance.

Pathogens have a few different mechanisms of action to evade destruction by disinfectants. Spore-forming organisms and mycobacteria have a more complex cell wall anatomy which affords them some intrinsic resistance (1). Gram-negative bacteria have an additional outer membrane which affords them some of the same (1). QACs have traditionally been considered to have poor efficacy against non-enveloped viruses such as norovirus and calicivirus, hence the significance of the latest formulation update (1). Pathogens that produce biofilms are often also able to evade biocidal activity- some strains of E.Coli for example.

Bacteria that possess efflux pumps are also able to eject some QACs from their cystoplasm, limiting their efficacy (1, 2, 3). Bacteria can also develop with plasmids (transferable sections of DNA) which can be selected and share genetic material coding for decreased tolerance (1, 2, 3).

It does remain unsubstantiated within the research as to whether pathogens are developing tolerance in practical situations (3). QACs tend to be used at concentrations much higher in the workplace than those tested in laboratory settings and under variable conditions; in vitro results have not yet consistently been recreated in real world settings (2, 3). Disinfection remains a key weapon in the ongoing war against antimicrobial resistance.

Safety in the workplace.

With the use of concentrated Safe4, clinics and institutions must be aware of the safety precautions necessary for proper storage and use, and the appropriate action to be taken in the case of accidental spillage. Where possible, stored products with the lowest concentration of hazardous substances present the safest option. Staff need to be trained ahead of use and personal protective equipment must be provided to ensure safe handling when diluting. The concentrated product is noted as being chemically stable under normal room temperature storage, must be kept away from acidic products and avoid extremes of temperature. Hazardous reactions may occur if inhaled in concentrated form and may cause serious eye damage if splashed onto the face. Masks, gloves and goggles (PPE) are advised to be worn when diluting into buckets and spray bottles and this activity should be done in a well-ventilated area. If an accidental spillage occurs, wear this PPE during cleaning (4).

If inhaled or splashed onto skin or eyes, the person should be immediately removed from the area into fresh air and the face, hands and eyes rinsed immediately with fresh water. Contact lenses should be removed if worn (4).

At working dilutions of 1:10, 1:50 and 1:100, the product is safe to be used without gloves, mask and goggles. Once applied to surfaces, these surfaces must be completely dry before animals are returned to the kennel.

The data sheet for the updated Safe4 concentrate along with independent analyses can be requested from the Scientific Communications team at SV Animal Health; sci-comms@sv-companies.com.

References

- Boyce, J.M. (2023) Quaternary ammonium disinfectants and antiseptics: tolerance, resistance and potential impact on antibiotic resistance. Antimicrob Resist Infect Control 12, 32. https://doi.org/10.1186/s13756-023-01241-z

- Buffet-Bataillon, S., Tattevin, P., Bonnaure-Mallet, M., & Jolivet-Gougeon, A. (2012). Emergence of resistance to antibacterial agents: the role of quaternary ammonium compounds–a critical review. International journal of antimicrobial agents, 39(5), 381–389. https://doi.org/10.1016/j.ijantimicag.2012.01.011

- Gerba C. P. (2015) Quaternary ammonium biocides: efficacy in application. Applied and environmental microbiology, 81(2), 464–469. https://doi.org/10.1128/AEM.02633-14

- UK Government Health and Safety Executive